constantan rockwell hardness test|rockwell hardness calculator : importers The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .

webSeason 1. Release year: 2023. With his straw hat and ragtag crew, young pirate Monkey D. Luffy goes on an epic voyage for treasure in this live-action adaptation of the popular manga. 1. ROMANCE DAWN. 65m. Stranded on a sinking boat, carefree Luffy begins his journey in search of a pirate king's lost treasure.

{plog:ftitle_list}

webThere are three ways to create epics in Jira Software: the Timeline, Backlog, and Global Create issue button. When you create an epic, you'll need to enter the following details: Epic name - A short identifier for your epic. This will be used as .

The Rockwell scale is a hardness scale based on indentation .Hardness of Nickel Alloys. Rockwell hardness of constantan – 45Ni-55Cu is approximately 50 HRB. Brinell hardness of superalloy – Inconel 718 depends on heat treatment process, but it .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .Rockwell Hardness Testing Reference Guide. ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

The purpose of this Guide is to explain the causes of variability in Rockwell hardness test results and to supplenment the information given in test method standards with .The Rockwell test is based on measurement of the depth of penetration with the hardness number read directly from the dial gauge or digital display that is part of every tester. In .

The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 .

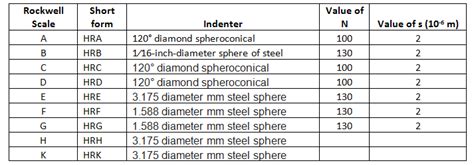

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the .Units of hardness. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges .Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). .

Rockwell hardness test Brinell hardness Vickers Knoop hardness Shore 3.1. Rockwell Hardness Test. The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load is applied. Hardness numbers have no units and are commonly given in the R, L, M, E and K scales.Common indentation hardness scales are Rockwell, Vickers, Shore, and Brinell, amongst others. Rebound hardness . but this is outside the scope of conventional hardness testing.) A hardness number is just a semi-quantitative indicator of the resistance to plastic deformation. Although hardness is defined in a similar way for most types of test .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .1. Define Hardness. 2. Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness Test. 4. Different Types of Hardness Testing Methods. 5. Size of the Ball to be used in Ball Indentor of Rockwell Hardness Test. 6. Di ameters of the different Balls used in Brinell .

Rockwell Hardness Testing Machine: Comes in different scales (A, B, C, etc.) to match various hardness levels and types of materials. Indenter: Usually, a diamond cone or hardened steel ball is selected according to the material under examination. Test specimen: the material or component undergoing evaluation. Methodology: Steps: 1.

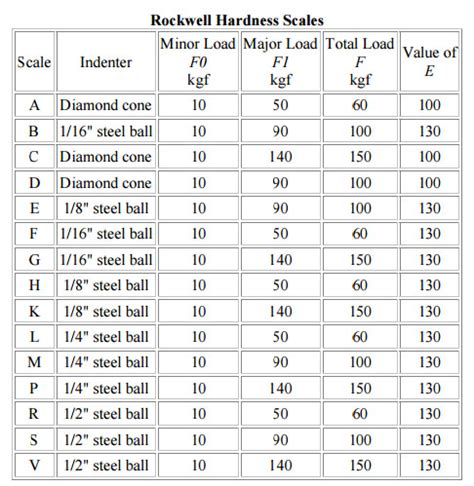

The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two force levels using the specific conditions defined in Clause 7. The specified preliminary force is applied The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of the indentation as the force on the .Rockwell hardness test is one of the most common indentation hardness tests developed for hardness testing. In contrast to the Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The minor load establishes the zero position .

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .The Vickers hardness test has received fairly wide acceptance for research work because it provides a continuous scale of hardness, for a given load, from very soft metals with a DPH of 5 to extremely hard materials with a DPH of 1,500. The Vickers hardness test is described in ASTM Standard E92-72. Rockwell Hardness Test ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

Rockwell regular hardness =100 0 002 − h, HRBW HREW HRFW HRGW HRHW HRKW Rockwell regular hardness =130 0 002 − h, HRN HRTW Rockwell superficial hardness =100 0 001 − h, 5 Rockwell hardness 5.1 The following is an example of the designation of Rockwell hardness. EXAMPLE 70 HR30TW, where:The Rockwell hardness test is the most common method for determining hardness of ferrous and many nonferrous metals. (See table below.) It differs from Brinell hardness testing in that the hardness is determined by the depth of indentation made by a constant load impressing on an indenter. In this test, a standard minor load is applied to set a .

Test Device U1 (UCI) Length 160mm Diameter 25mm Indentation Depth 30µm Pressure Force 14.7N Transducer Test Life (approx) 200,000 Min. Thickness for test 1mm Min. Radius for Test 5mm Max Roughness of surface Ra 2.5µm Max Archive 100 Tests Time of Test 4 sec. Comparison of Hardness Testing Methods-Phase II Models shown below Data Dynamic .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . The Rockwell hardness test is divided into various scales, each with a wide range of applications. (5) It is important to note that Rockwell hardness values obtained from different scales are not comparable. 4 .

4) For Rockwell hardness testing, no optical measurements are required; all readings are direct. There are two common methods applied to measure material hardness macroscopically: Rockwell and Brinell. Rockwell hardness differs from Brinell hardness testing in that the indentation size is measured in Brinell

Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F HB − − = π 2 1.854 D F HV =The Rockwell hardness test. Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter has been forced into the specimen material at a given load.

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

3 how have tests had a historically positive impact

See also: Hardness Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with . Figure 1. An operator performing a Rockwell hardness test. (Source: Arkansas Department of Transportation.) The Rockwell hardness is calculated using the following formula: Rockwell Hardness, HRC = [0.2 – permanent depth of indentation (mm)] x 500. The Rockwell hardness test was developed to be less destructive and cheaper than the Brinell test. The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.

rockwell steel scale

rockwell scale size chart

Jewel Star. Casual Classic Puzzle Windows version brought to you by Rolling Donut Apps. Connect 3 or more jewels together to make them disappear. Match lightning, blast, and star jewels for bigger bonuses and combos. With easy to use controls, fun and friendly graphics, and over 200 levels to play, this game is fun for the whole family!

constantan rockwell hardness test|rockwell hardness calculator